- Join our Team

- Resources

-

Account

- |

- Cart

- EN FR

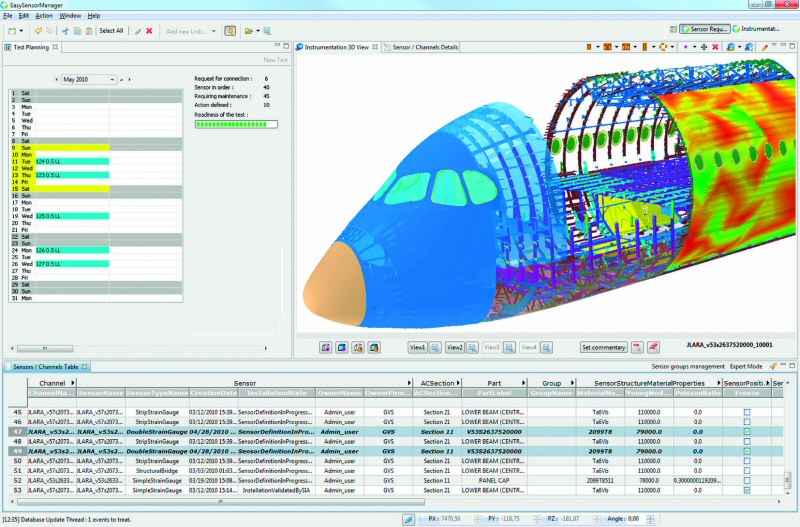

Global Vision Systems uses Datakit software to convert CAD models of an Airbus A350

June 17, 10

The vendor of 4D supervision and instrumentation PLM solutions is using conversion

software from the data exchange specialist.

Global Vision Systems (www.global-vision-systems.com) is a vendor of solutions for industrial supervision. The start-up was founded in 2007 in Toulouse by two engineers, David Croenne and Baptiste Gendron Canion, who worked together as consultants at the German Space Operations Center (GSOC).

Global Vision Systems currently employs some twenty people.

The company’s flagship is EasyMonitoring, an ergonomic platform that facilitates the supervision and

analysis of complex systems in their working environment:

“When we were at GSOC we were surprised to see that the data transmitted by the sensors on board the satellites was being displayed as graphs or 2D diagrams”, explains David Croenne. “Yet telemetry can generate up to 5,000 items of data per second. We figured that with 3D we could display more information in real time and consequently interpret the signals more accurately. For example, it’s easier to spot an overheating issue when you see a duct change color in a three-dimensional environment. 3D also lets you view more information at a specific instant, better assess the impact of incidents, and take the right decisions faster. This is why we use the term 4D visualization, which includes the real-time dimension.”

PLM for instrumentation

EasySensorManager is the second part of the Global Vision Systems offering. Presented as “PLM for instrumentation”, the application offers a simple graphic human-machine interface in which to implement test equipment in a digital mockup of a supervised environment.

The applications will initially be targeting big aerospace groups, and Airbus was the first user in industry, preparing and monitoring static and fatigue tests on the A350 (illustrated below).

More than 40 GB of native CATIA

Both EasyMonitoring and EasySensorManager feed on geometric data from industrial machinery or

installations (both products can be used in the supervision and management of control systems in large facilities such as refineries).

“To maintain a display quality compatible with real time applications we had to find a data format that would be lightweight while still allowing our customers to incorporate their own native CAD

data,” explains David Croenne. “The reputation of Datakit’s API, and having so many references among the leading CAD and 3D viewer vendors persuaded us to integrate its know-how into our applications in a way that would be transparent to end users”.

This gave the team at Global Vision Systems the freedom to focus on its own know-how in supervision and instrumentation, while offering existing and potential customers complete access to their CAD heritage.

“Datakit is particularly proud to have been selected by Global Vision Systems”, says Francis Cadin. “The whole team is delighted not only to be working for the established players in CAD but also for young, innovative companies. It has been even more exciting to work with Global Vision Systems who forced us to push back the limits of our converters, especially in terms of the volumes of data we can handle.”

Take the example of an Airbus: though users may choose to import just part of a digital mockup, an

aircraft’s geometric data still adds up to big numbers. “We find ourselves feeding up to 40 GB of native CATIA data into the converter. We are aware that we set Datakit quite a challenge, but the support they gave us more than met our expectations”, reports David Croenne.