- Join our Team

- Resources

-

Account

- Cart

- EN FR

From the transfer of associative 3D annotations and to the tolerancing & dimensioning data or the validation Properties: hard job for the members of the Cax-IF forum

November 01, 07

For many years, Datakit has been actively involved in defining and developing the STEP standard; and participates regularly in the Cax Implementor Forum (CAx-IF), where STEP converters are discussed, tested and evaluated.

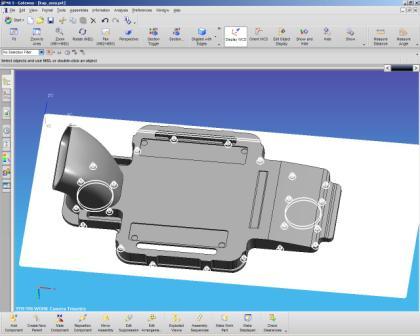

This year's autumn meeting was held at Darmstadt, Germany, and focused on the STEP AP203 and AP214 versions. A topic that came under particularly close scrutiny was the transfer of associative 3D annotations and tolerancing/dimensioning data. The LOTAR (“Long Term Archival and Retention”) Group, also presented its work and recommendations for data exchange and data quality. The tests and discussions that are common ground for LOTAR and CAX-IF, provide the basis for defining directions for the development of the use and upgrade of STEP, as well as recommended practices for its use in data exchange.

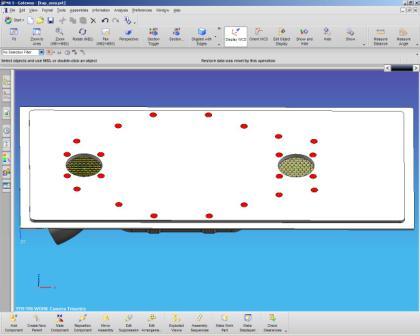

- The tested 3D annotations are presented in different forms, including more or less complex texts associated with a geometrical element, and may include special characters such as symbols.

- The GDT (geometric & dimensional tolerances) theme concerns the ability for a target software to reread this type of data from a source 3D model. The data can be stored with the geometry in long-term archives. The QC and manufacturing departments have a very real interest in a comprehensive capability for recovering all the data that is traditionally supplied to them on two media: the digital model and the set of paper drawings.

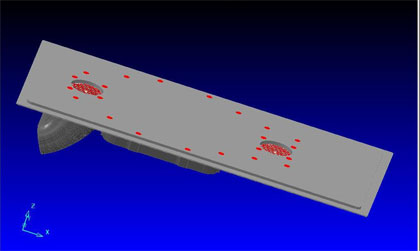

Validation Properties accompany the STEP model and are used to validate the quality of exchanged CAD data or for long-term archiving purposes. Validation Properties concern the general properties of the geometrical model (volume, surface, centre of gravity of solids) and the assembly properties (enabling component position to be checked).

The local properties are defined by Clouds of PointS or COPS attached to the faces and edges of the 3D model. A sample attached to each exported face, enables distances between these points and the faces and boundaries of the surfaces in the imported geometry to be compared. The aim of this development then is to enable self-checking and long-term archiving.

The ability to check data quality is a major preoccupation of the participants, particularly the Lotar group, whose aim is to ensure that data is correct and can be properly read back, years later. The definition of formal procedures for checking and defining the required quality level is in progress.

In addition to these test subjects linked to specific functionalities, Datakit is also involved in work on the quality of exchanges of part and assembly files that characterise the aeronautic and automobile industries.

PDES, Inc and PROSTEP member companies supply test models that have to be exported in STEP AP214-IS or AP203e2 format, along with commentaries on the results obtained, including validation properties.

For Christian Caillet, the STEP specialist in Datakit's R&D team, “the conditions in which these tests are conducted, and the ongoing technical discussions, offer a genuine opportunity to make objective and regular decisions on the suggested level of solutions, and also to get a clear look at the changing needs expressed by the software developers and manufacturers who attend these meetings. It is a unique opportunity for engineering professionals to exchange ideas, pool efforts and take the technology further down the road.”

Pictures published with courtesy of CAx-IF and Rockwell Collins